Develop Smarter: Exactly How Aftermarket Construction Parts Can Improve Your Profits

Develop Smarter: Exactly How Aftermarket Construction Parts Can Improve Your Profits

Blog Article

Increase Efficiency With Aftermarket Parts: an Overview for Heavy Machinery Owners

Advantages of Aftermarket Parts

Owners of hefty machinery can enjoy various benefits by selecting aftermarket components over initial devices producer (OEM) parts. Among the primary advantages is expense savings. Aftermarket components are normally more inexpensive than OEM parts, permitting equipment proprietors to decrease maintenance and repair expenses without jeopardizing on high quality. In addition, aftermarket parts usually include warranties, ensuring that purchasers are safeguarded in situation of any kind of problems or problems.

Because aftermarket producers specialize in generating specific elements, machinery owners have accessibility to a broader variety of options to suit their demands. Aftermarket components are understood for their top quality and dependability, with numerous meeting or exceeding OEM standards.

Lastly, selecting aftermarket parts can also lead to faster fixings and decreased downtime. With less complicated availability and quick delivery options, machinery owners can get their equipment up and running once again swiftly, decreasing interruptions to their operations.

Selecting the Right Aftermarket Parts

When thinking about aftermarket parts for heavy machinery, it is necessary to focus on compatibility and top quality to guarantee optimal performance and longevity of the devices. Picking the right aftermarket components can be a crucial decision for hefty equipment proprietors as it straight influences the effectiveness and reliability of their equipment.

Secondly, top quality must never be jeopardized when choosing aftermarket components (aftermarket construction parts). Choosing for high-grade components makes certain durability, dependability, and general efficiency of the equipment. It is advisable to source aftermarket parts from credible suppliers or distributors understood for their high quality criteria

In addition, considering elements such as service warranties, client evaluations, and compatibility with existing systems can better assist in making the appropriate choice. By focusing on compatibility and top quality when choosing aftermarket components, hefty machinery proprietors can improve the effectiveness and longevity of their equipment.

Setup and Maintenance Tips

For effective operation and long life of hefty machinery, appropriate installment and regular maintenance are extremely important. When installing aftermarket components, make sure that you very carefully adhere to the manufacturer's instructions to assure optimum performance. By focusing on installation and maintenance procedures, you can maximize the effectiveness and life expectancy of your heavy machinery, inevitably saving time and money in the long run.

Cost-Effectiveness of Aftermarket Components

Appropriate installment pop over to this site and normal maintenance are fundamental facets for heavy equipment owners intending to evaluate the cost-effectiveness of aftermarket parts for their tools. While original tools producer (OEM) components are recognized for their top quality, aftermarket parts supply a more cost-efficient remedy without endangering efficiency. By carefully evaluating the quality and compatibility of aftermarket parts with their machinery, owners can strike a balance in between cost-effectiveness and efficiency, ultimately maximizing the effectiveness and long life of their hefty devices.

Taking Full Advantage Of Effectiveness With Aftermarket Upgrades

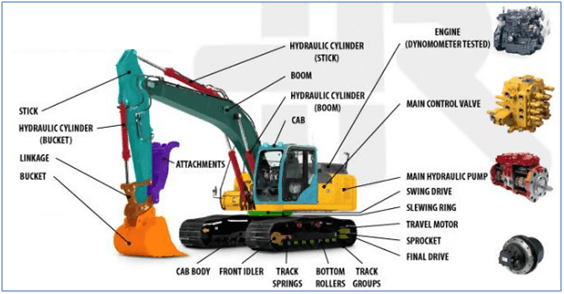

To boost operational performance and performance, hefty machinery proprietors can effectively maximize efficiency through tactical utilization of aftermarket upgrades. Aftermarket upgrades offer the chance to customize hefty machinery to specific operational demands, causing improved functionality and result. Upgrading components such as engines, transmissions, hydraulic systems, and tracks can considerably improve the general performance of the machinery.

Regularly evaluating click this site the efficiency of heavy machinery and identifying areas where aftermarket upgrades can be valuable is crucial for making best use of performance. By spending in quality aftermarket parts and upgrades, equipment owners can achieve greater degrees of effectiveness, ultimately bring about cost savings and boosted functional end results.

Conclusion

To conclude, aftermarket components provide many advantages for heavy equipment proprietors, consisting of cost-effectiveness, increased performance, and modification options. By picking the appropriate aftermarket components, following proper installation and upkeep treatments, and maximizing upgrades, hefty find here equipment owners can increase their tools's performance and durability. Investing in aftermarket parts can ultimately cause enhanced productivity and reduced downtime, making it a rewarding consideration for owners wanting to enhance their equipment operations.

Owners of heavy equipment can appreciate many advantages by deciding for aftermarket parts over original tools supplier (OEM) parts. Aftermarket components are generally more cost effective than OEM components, enabling equipment owners to lower maintenance and fixing costs without endangering on high quality. By very carefully evaluating the high quality and compatibility of aftermarket components with their machinery, proprietors can strike a balance between cost-effectiveness and performance, ultimately making the most of the performance and long life of their heavy equipment.

In verdict, aftermarket components offer countless advantages for heavy equipment owners, including cost-effectiveness, raised effectiveness, and customization options. By choosing the ideal aftermarket components, following appropriate setup and maintenance procedures, and making best use of upgrades, heavy machinery proprietors can improve their devices's performance and long life.

Report this page